Levan Engineering Ltd

#263 7620 Elbow Drive SW

Calgary, AB T2V 1K2

ph: 403-701-2466

bruce

in-situ Metallography

If there is creep damage, fire damage or a defect, we can cut a section out of the pressure equipment. And examine the microstructure in the lab. I can determine if the equipment can remain in-service. But this is a destructive test.

Or I can take a replica of the pressure equipment surface and examine the microstructure in the field with a portable microscope. I can obtain much of the same information as in the lab. This is called in-situ metallography and this test is nondestructive.

In-situ metallography of SA-106 grade B boiler tube. This image shows ferrite grains and some carbide particles. Creep voids (blue) and creep microcracks (red) are at the grain boundaries.

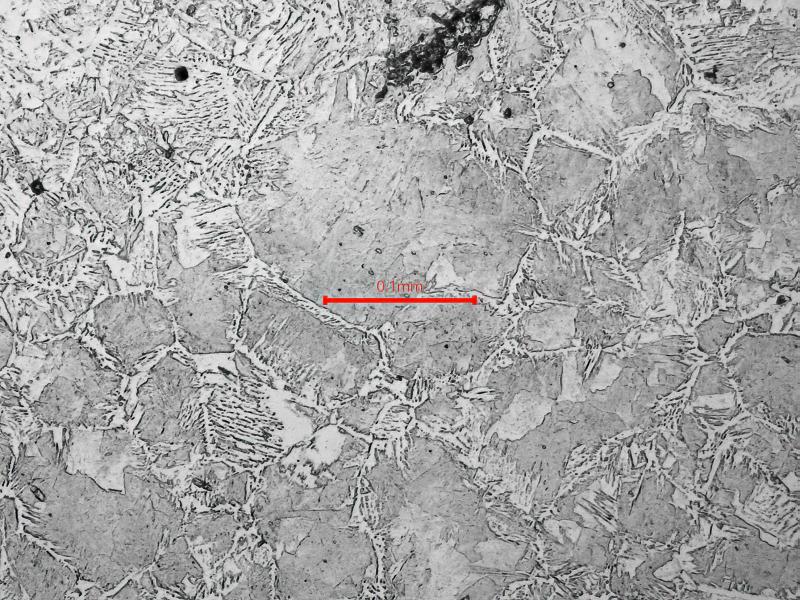

This is in-situ metallography on the weld and HAZ of SA-516 grade 70 steel. There are some weld inclusions at the top left corner. The remainder is the HAZ and it consists of grain boundary ferrite and some upper bainite. But there is no creep damage.

Copyright 2014 Levan Engineering Ltd. All rights reserved.

#263 7620 Elbow Drive SW

Calgary, AB T2V 1K2

ph: 403-701-2466

bruce